Urschel Test Lab

Urschel, a leading manufacturer of food processing equipment, approached Sharpe Engineering with a specialized challenge: to help design and build a fully operational test lab that mirrored a field-ready manufacturing plant. The facility would provide prospective clients with the ability to physically test equipment and processes, supporting a “seeing is believing” hands-on sales approach.

Problem

Creating a versatile automated system and providing the necessary ancillary equipment, utilities, and external environment to closely replicate that of a real production floor.

The lab needed to accommodate a wide range of products—including soy milk, oat milk, nut butters, fruit purees, coconut products, and more—while handling high viscosity and flow rates across various “Comitrol” configurations. Supporting components and sanitation capabilities were required to accurately portray the Urschel equipment’s capabilities.

Solution

Sharpe partnered with Urschel to provide a fully integrated solution, enhancing and complementing Urschel’s industry-standard equipment. Sharpe’s scope of work extended from feasibility and system design through installation and commissioning.

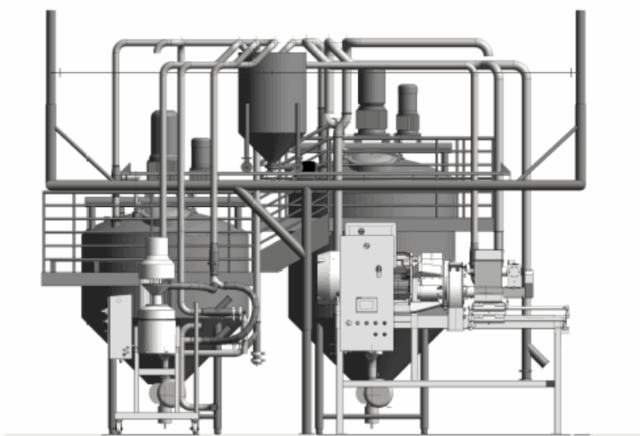

Partnered with Urschel, the Sharpe team filled critical gaps to create a complete “Comitrol” bundle, comprised of the following components:

- Custom stainless-steel tanks- with scrape agitation for challenging applications

- Pumps and mobile pump hopper carts- for flexible product flow

- Pipe panels and hose connections- for configuration versatility

- Platforms and mezzanines- for accessibility and operability

- Bulk handling and conveying systems

- CIP systems and control integration

Specific equipment that Sharpe designed and integrated were the following:

- 600-gallon and 1000-gallon jacketed tanks- with full scrape agitation for handling thick and high-throughput products

- High-pressure hot water boiler- with dual-loop capability—one for tank jackets, one for product hydration and cleaning

- Gravity-fed tank system- allowing natural flow rates to Comitrol 1700 (30 GPM) and Comitrol 9310 (80 GPM)

- Rotary lobe pump cart- designed for mobility and multi-mill operation

- Inline instrumentation- to track product density, throughput, and temperature

- Cone-bottom tanks with side scrape agitators

- 20HP twin screw discharge pumps

Results

Combining Urschel’s world-class processing machinery with Sharpe’s turnkey custom solutions, the result is a flexible, sanitary, and high-performance test facility that reinforces trust and streamlines the path from trial to production.

- Customized support for industry-leading OEM’s, like Urschel, with custom-engineered systems

- Delivery of comprehensive field services and process integration

- End-to-end project execution from design to commissioning

- Solving of complex technical challenges, allowing for an efficient customer facing operation

Ready to speak with our team of experts?

Feel free to give us a call, email, or fill out a short inquiry— let’s complete your project together.