Platform Mounted Washer Integration

A food processing facility required an upgraded sanitation system to enhance operational efficiency and meet rigorous hygiene standards. Their existing cleaning equipment was outdated and unable to support their production demands effectively. Additionally, space constraints, worker safety and operational flow required the new system to be platform-mounted to optimize floor space and eliminate risks associated with transporting components from one elevation to another.

Problem

The manufacturer needed to optimize their sanitation system, with significant space constraints not allowing for a typical floor mounted cleaning system.

Sharpe Engineering played a critical role in addressing these challenges by providing front-end guidance and unbiased evaluation. The success of the project hinged on effectively managing several key factors.

Timeline Management: Coordinating activities among multiple stakeholders to meet tight project deadlines and ensure timely delivery.

Design Complexity: Integrating the new production line seamlessly into the facility’s existing infrastructure while addressing spatial and technical constraints.

Operational Standards: Maintaining strict compliance with safety protocols and industry regulations throughout the design and installation process.

Solution

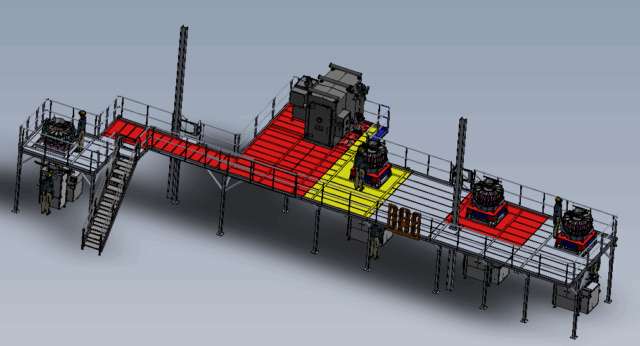

Sharpe Engineering partnered with Sani-Matic to develop and implement a Custom SaniCab P365 Cabinet Washer mounted on an elevated platform. This solution provided seamless accessibility, improved workflow efficiency, and ensured proper integration with the facility’s layout. Key features included:

Custom Equipment Design

- Inflatable door gasket

- Eight custom racks with ID tags

- 45kW electric dryer and heater

- Remote access via SaniTrend Cloud

- 3D component modeling

- Two chemical pumps for precise cleaning

- Tempering valve to drain

- PVC-coated rigid conduit for durability

- Rack pullout hook and spare pullout tray

Engineering and Fabrication

- Platform-mounted washer design to maximize floor space

- Structural frame assembly for safe and stable mounting

- Existing equipment evaluation

- Utility matrix and exhaust system integration

- Drain design with removable panels for safety and access

Phased Installation Approach

- Phase 1: Initial layout, washer specification, and utility planning

- Phase 2: Custom rack and platform fabrication

- Phase 3: Installation of the platform, washer mounting, utility connections, and final commissioning

Results

Sharpe Engineering’s expertise in platform-mounted sanitary equipment solutions provided the client with a turnkey integration that improved efficiency, safety, and reliability. By collaborating with Sani-Matic and leveraging precision engineering, we delivered a customized, high-performance sanitation system tailored to the client’s operational needs.

- Optimized Space Utilization: The platform-mounted design preserved valuable production floor space while ensuring easy access for operation and maintenance.

- Enhanced Cleaning Efficiency: The cabinet washer streamlined the sanitation process, reducing labor time while improving cleanliness.

- Seamless Infrastructure Integration: The elevated system was engineered to fit within the facility’s footprint without disrupting existing workflows.

- Increased Equipment Lifespan: The solution’s robust design and material selection enhanced durability and longevity.

- Flexible Scheduling & Execution: The project was managed in phases to accommodate production schedules, ensuring a smooth transition.

Ready to speak with our team of experts?

Feel free to give us a call, email, or fill out a short inquiry— let’s complete your project together.