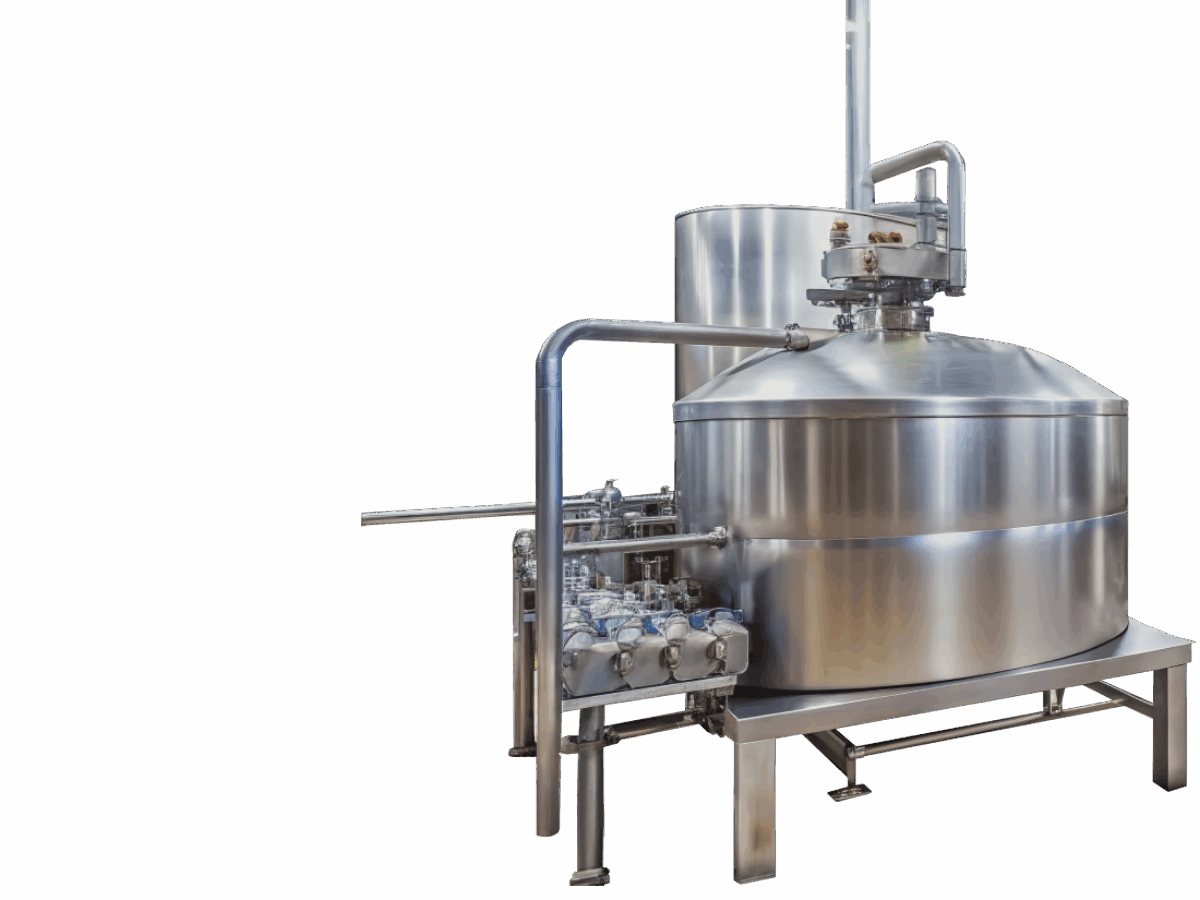

Sanitary Process Systems

Maintaining the highest standards of cleanliness is critical for operational efficiency and product safety. At Sharpe Engineering, we specialize in designing, implementing, and optimizing sanitary process systems that ensure your facility operates smoothly and meets strict regulatory requirements. From automation to cleaning solutions, our team delivers custom-engineered systems that improve productivity, minimize waste, and enhance employee safety.

Custom Process Solutions

At Sharpe Engineering, we offer a complete suite of solutions to meet all your sanitary process system needs. From engineering and design to installation and automation, we ensure that your facility operates efficiently and meets the highest hygiene and safety standards.

Design & Installation

We deliver complete design, engineering, and installation solutions for sanitary systems, ensuring seamless integration and minimal downtime.

Automation

Our tailored automation systems enhance efficiency and safety, with a focus on both new and legacy equipment.

System Evaluation

We identify inefficiencies in your current processes and provide actionable recommendations to improve performance and sanitation.

CIP & COP Systems

Our CIP and COP solutions reduce chemical use, improve safety, and ensure thorough cleaning for all system components.

Process Piping & Installation

We specialize in designing and configuring process piping systems built for optimal flow, sanitation, and efficiency. Our construction and installation services adhere to the highest industry standards, ensuring that every system meets regulatory requirements and your operational needs. During startup, we provide hands-on support to ensure everything functions flawlessly, minimizing downtime and setting your facility up for long-term success.

Ready to optimize your sanitary process systems?

Reach out to our team today and discover how we can help elevate your operations.