Project Management & Engineering

At Sharpe Engineering, we have partnered with food and beverage manufacturers since 1994, managing a wide range of projects from large-scale greenfield developments to smaller initiatives focused on operational efficiency. Our flexibility in project size and scope allows us to tailor resources to fit your specific needs, ensuring every project is completed efficiently and successfully. Whether it’s offering full-service project management or dedicated resources for specialized tasks, we are committed to delivering on-time and on-budget results.

Comprehensive Project Management & Engineering Services

We break down our services into distinct phases to ensure clarity, efficiency, and focus at every stage of the process. Explore our capabilities below, designed to support your project from initial concept through successful execution and ongoing support.

Scope Development

From the initial project concept to defining clear objectives, our team ensures that your project is thoroughly scoped. We provide a review of requirements and constraints, laying the foundation for success from day one. This stage sets the tone for budget, timeline, and execution expectations, ensuring all parties are aligned before any work begins.

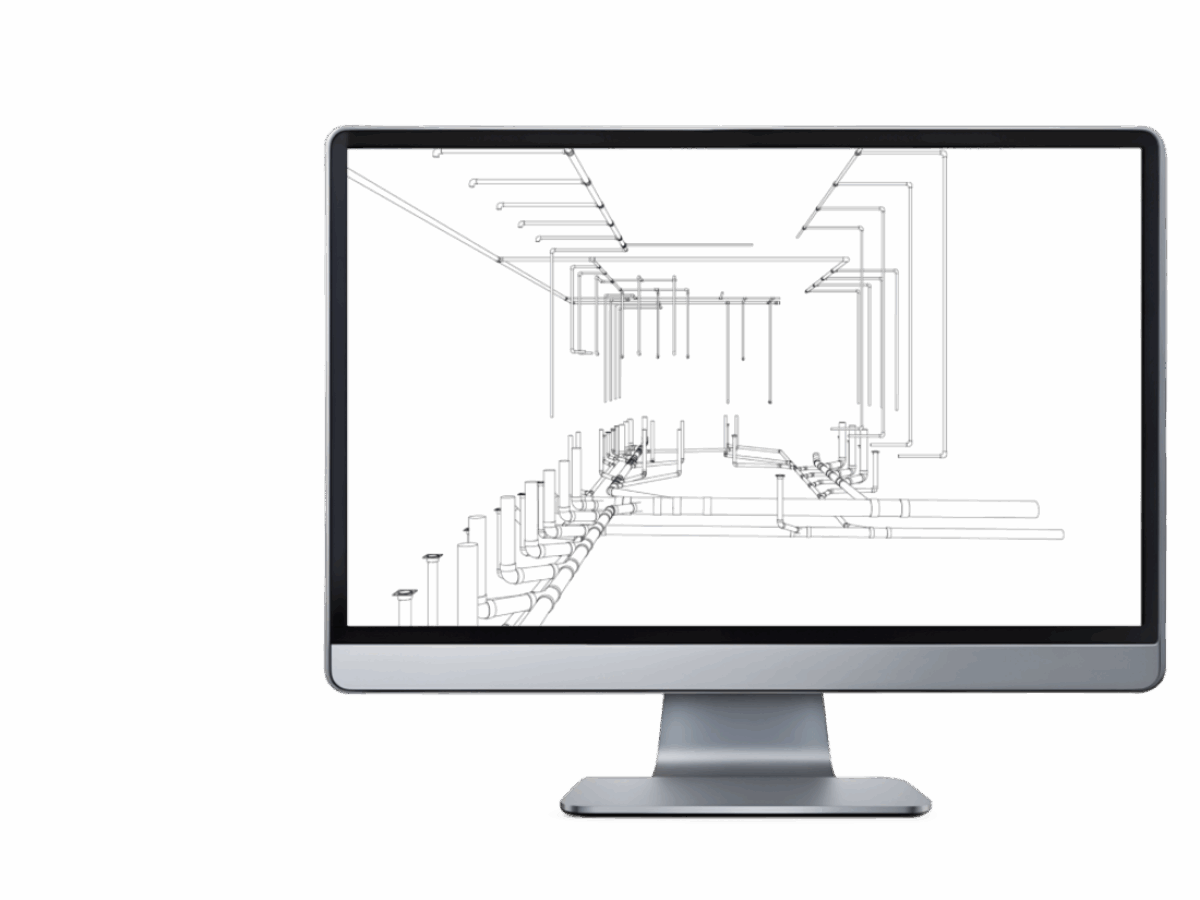

Engineering & System Design

Our engineers design solutions that are both innovative and practical. With a deep understanding of food and beverage manufacturing, we develop systems that optimize your facility’s performance, focusing on efficiency, scalability, and sustainability. We ensure compliance with industry regulations while creating custom solutions tailored to your needs.

Project Management

With decades of experience in project management, we handle everything from scheduling, budgeting, and resource allocation, to vendor coordination and risk management. We utilize industry best practices to keep your project on track and maintain transparency at every stage with detailed reporting and communication.

Project Execution

Our project execution is defined by precision and proactive management. From initial design to final handoff, we maintain a clear focus on achieving project goals, mitigating risks, and ensuring that timelines and budgets are met without compromising quality.

Installation & Start-Up

We oversee every aspect of installation, ensuring that systems are correctly implemented and integrated within your existing operations. Our team works with precision to minimize downtime and ensure a seamless start-up with quality control points, testing, and troubleshooting built into the process.

Ready to speak with our team of experts?

Feel free to give us a call, email, or fill out a short inquiry— let’s complete your project together.